Login

Risk analysis

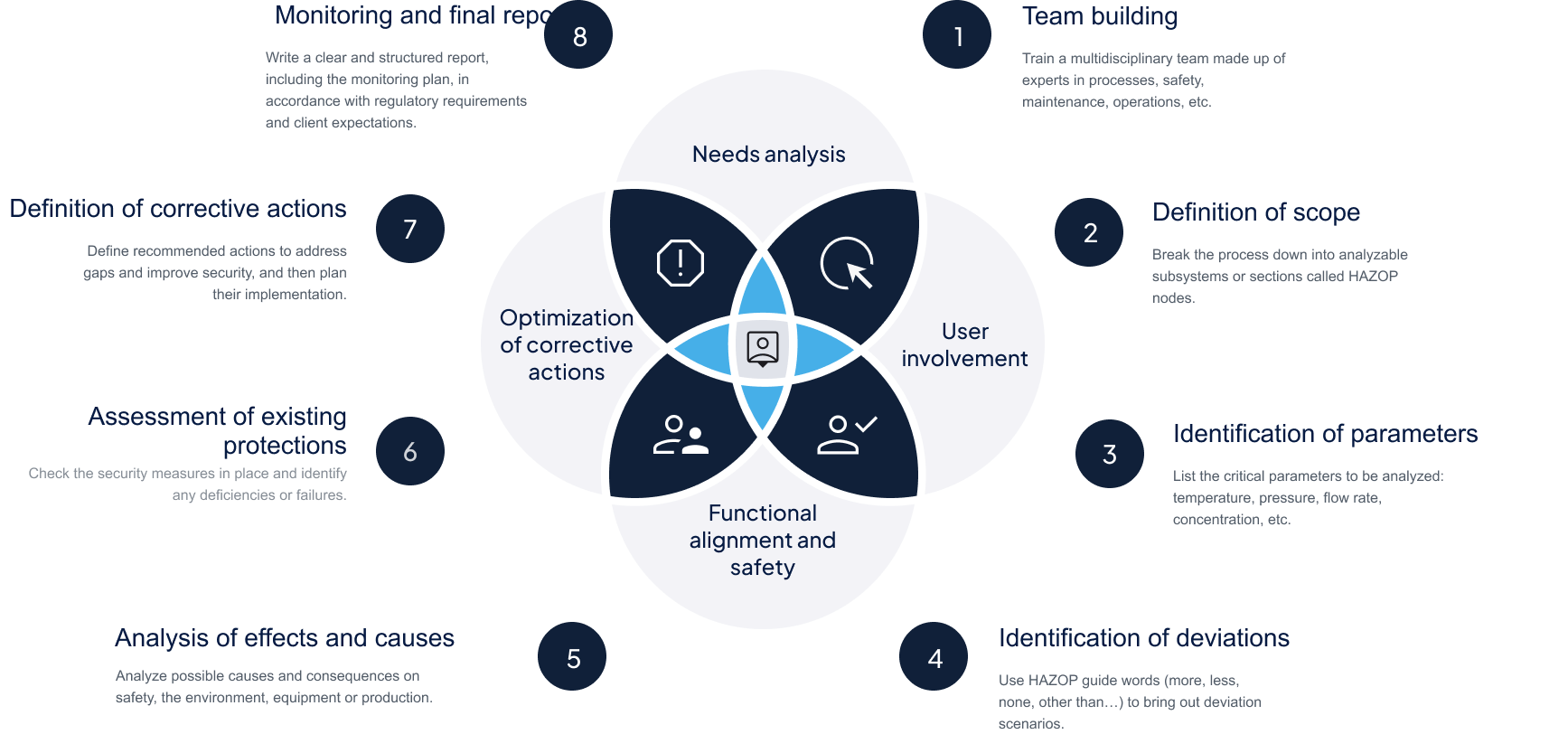

The HAZOP method (Hazard and Operability Study) is one of the most widely used approaches for assessing operational risks in complex industrial processes. It is based on a structured analysis of deviations in operating parameters that could lead to hazardous situations or performance losses.

With a HAZOP study, you benefit from:

numtech expertise

Process

Process

use case

We conduct HAZOP studies for a wide range of industrial processes. Our services notably cover the following sectors:

Each assignment is tailored to the specific features of your facilities and aims to enhance the safety, reliability, and regulatory compliance of your processes.

F. A. Q

|

|

|