Login

Risk analysis

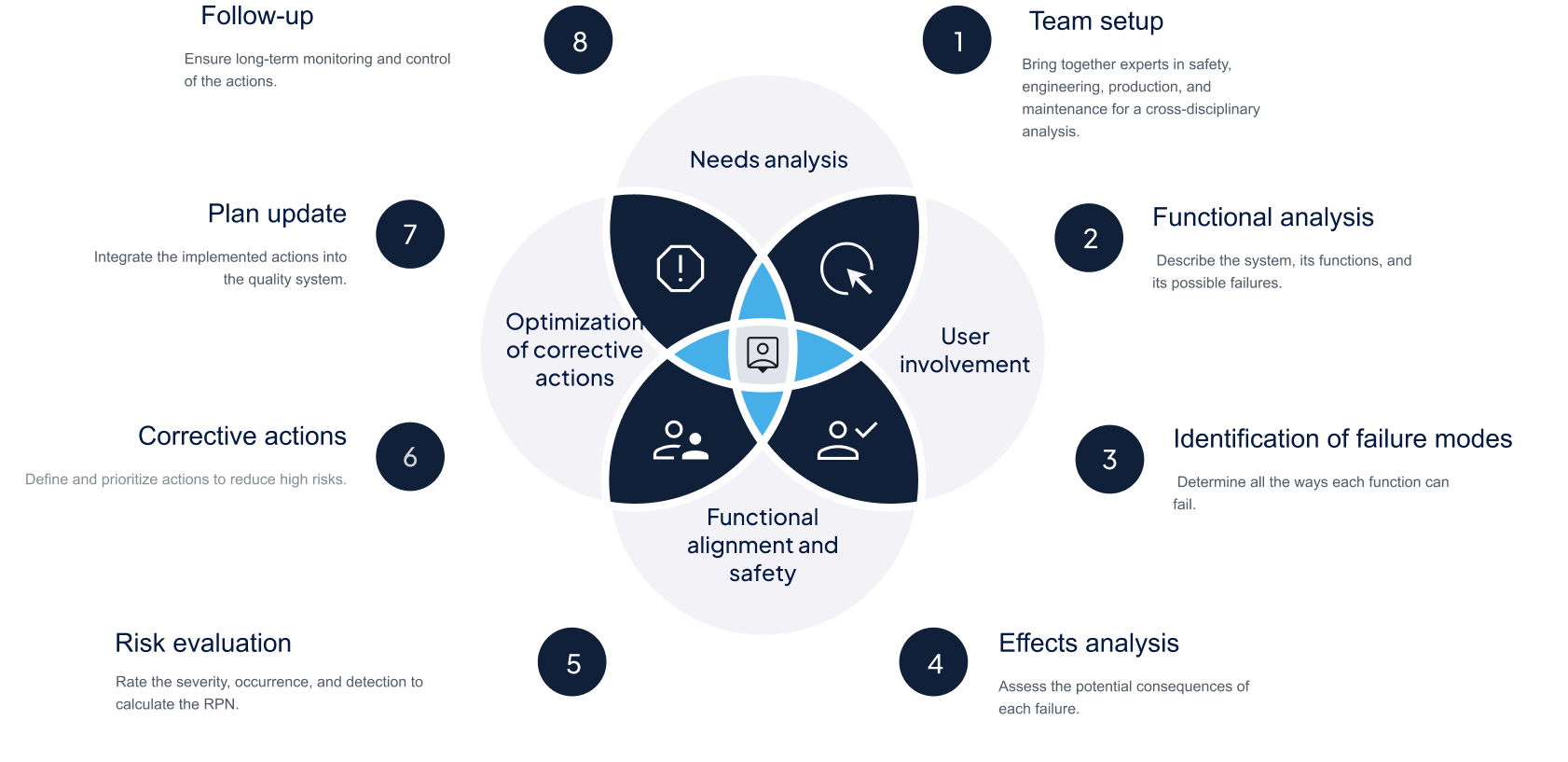

FMEA (Failure Modes, Effects, and Criticality Analysis) is a risk analysis method that helps identify potential failures, whether at the scale of an industrial site, during product design, or in process implementation. It measures their consequences, ranks their criticality, and defines the preventive actions to be implemented.

We carry out FMEA studies for a variety of industrial systems. We operate in the following sectors in particular:

numtech expertise

Identify equipment failures, human errors, and process malfunctions.

For each failure, determine the possible consequences on performance, employee safety, the environment, and installations.

Calculate a Risk Priority Number (RPN) by considering the severity, occurrence, and detectability of the failures.

Prioritize the actions to be taken to reduce or eliminate identified risks.

Process

Process

use case

We carry out FMEA studies for various industrial systems and support our clients in different sectors, including:

Each intervention is tailored to the specific features of your facility and your requirements for safety, reliability, and regulatory compliance.

F. A. Q

|

|

|